How Matt Reduced His Inventory Costs From 25% To 18% Of Total Revenue

DESCRIPTION:Matt has sold over $17 million as a top seller in one of the most competitive categories on Amazon.com. He knew how to start and grow a business. What he didn’t know was how to optimize his supply chain to maximize profits. After working with us Matt was able to increase his profit margins dramatically and save $100,000's per year in unnecessary costs.

Other Results

27 Videos

keyboard_arrow_down

![[object Object]](https://images.prismic.io/intoprofits-2024/65835bb3531ac2845a26d59c_kunle-campbell-thumb.png?auto=format,compress)

Kunle Campbell

United Kingdom

![[object Object]](https://images.prismic.io/intoprofits-2024/ZlnrkaWtHYXtT-rb_Ana.png?auto=format,compress)

Ana Popescu

Germany

Andrius Jurkevicius

Lithuania

![[object Object]](https://images.prismic.io/intoprofits-2024/65835bb2531ac2845a26d59b_evi-thumb.png?auto=format,compress)

Evi Kathrepti

Greece

![[object Object]](https://images.prismic.io/intoprofits-2024/65835bb1531ac2845a26d59a_charmaine-davis-thumb.png?auto=format,compress)

Charmaine Davis

United Kingdom

![[object Object]](https://images.prismic.io/intoprofits-2024/ZlYRiKWtHYXtT3Yk_Shirley.png?auto=format,compress)

Shirley

New York, United States

![[object Object]](https://images.prismic.io/intoprofits-2024/ZlYS76WtHYXtT3Y7_Christine.png?auto=format,compress)

Christine McVeigh

Perth, Australia

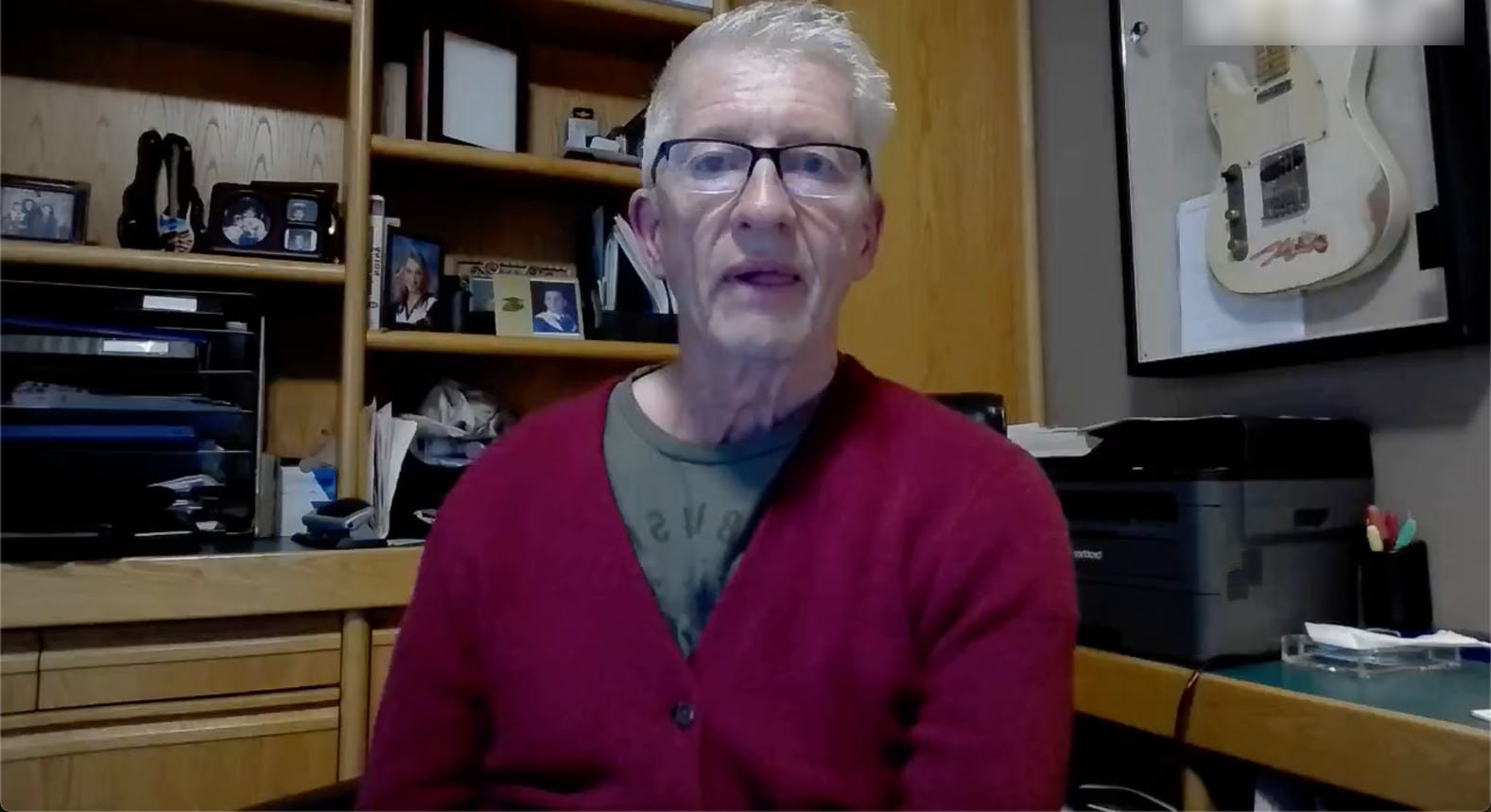

Terry Smith

Canada

![[object Object]](https://images.prismic.io/intoprofits-2024/65835bb5531ac2845a26d59e_richard-thumb.png?auto=format,compress)

Richard Turnbull

United Kingdom

Bill F.

Colorado, United States

Ben Luong

Birmingham, United Kingdom

![[object Object]](https://images.prismic.io/intoprofits-2024/65835bb4531ac2845a26d59d_matt-hodge.png?auto=format,compress)

Matt Hodge

Australia

![[object Object]](https://images.prismic.io/intoprofits-2024/Zk0PhCol0Zci9VXp_Troy.png?auto=format,compress)

Troy

Washington, United States

David Storey

United Kingdom

Michael Landgraf

Cyprus

James Boyd

United Kingdom

Lee Ackerman

London, United Kingdom

Shane C.

Dublin, Ireland

Roberto Auriemma

United Kingdom

Jamie Sukroo

United Kingdom

Tom Nutter

Portugal

![[object Object]](https://images.prismic.io/intoprofits-2024/657a0342531ac2845a2649d0_steven-winata-thumb.jpg?auto=format,compress)

Steven Winata

Arizona, United States

Tobias Schabanowski

Germany

Mo Mullah

London, United Kingdom

Hardeep C.

Los Angeles, United States

Esteban Araya

New York, United States

Brian Silverman

New York, United States